People often ask 2 questions.

Firstly, which arm is best for my particular deck and/or cartridge?

The answer is simply that all Origin Live arms work well with all decks and cartridges. Unlike many arms, there are no synergy or compatibility issues to consider.

Compliance: If you wish to optimise your cartridge compliance with the arm, we offer headshell weights of 2, 5 and 10 grams. Compliance matching is audible but of relatively minor importance compared to other factors in arm performance. Testing reveals that a poor compliance match with a better arm design will track and perform much better than a lesser arm with a perfect compliance match.

Secondly, how much should be invested in an arm due to the law of diminishing returns?

This question is more involved and the following points may help in coming to your own conclusions.

- There is no point at which you will stop hearing the difference a better arm makes, regardless of your system.

- Better arms reduce record wear due to reduced “chatter”

- You get significantly better performance £ for £ upgrading an arm than you would by investing the same on a Cartridge.

- Owning a better arm means you achieve better performance whilst running much cheaper cartridges. in the long run, this represents significant savings every time you need to replace your cartridge.

- Consider a balanced investment across components in the front end of your system. If your phono stage is poor then you are best off budgeting proportionally. For Origin Live turntables we recommend front end split should be approximate:

30% Turntable, 30% Tonearm, 30 % Phono-Stage, 10% Cartridge - Compare Origin Live tonearm features

For Rega arm mounts (221mm effective length arms) – Origin Live arms have a threaded base mounting that fits all arm-boards designed for Rega arms. This is literally a fuss-free drop-in replacement with no modifications needed, regardless of whether the Rega arm has a threaded base or 3 point mounting.

This is the simplest case so we put it first. Rega arms and their modified versions (i.e Michell, NAD etc) are easy to replace with an Origin Live arm. All standard length (239mm) Origin Live arms will fit directly into all standard Rega armboard mounts. No additional holes are needed, no modifications, no extra fittings, no VTA adjusters. This easy swap is down to the geometry of Origin Live arms being identical to all Rega arms.

It makes no difference if the Rega mount you have is the later 3 point mounting or earlier single hole mounting. Neither does the model number or vintage of a Rega arm make any difference.

The only question some people raise after fitting their Origin Live arm is that 3 mounting holes remain visible if the mount is the 3 point type of Rega mount. The solution to tidy up the looks is either to fill the 3 holes with dummy round head M3 Allen bolts or you can order a 1mm thick Formica black disc from us to cover the holes > see link Disc to cover 3 Rega mounting holes. Other solutions include simply cutting a cover disc from a black card or thin plastic.

Armboards & Mounting Position

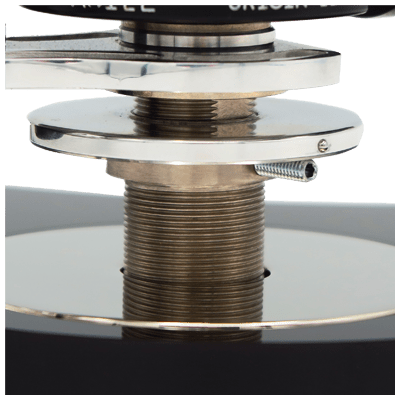

Hole Diameter: You can fit Origin Live arms to any deck but sometimes your armboard may need modification or changing to a new one – (contact a dealer or the turntable manufacturer for the second option). The tonearms require a single hole in the armboard or plinth – from 23mm to 25mm in diameter (23mm is ideal for accurate fit). If the hole in your armboard is say 1mm or more oversize then all you need to do is centralize the arm in the hole. For best performance, you do not want a tight fit and so all you need to do is put a rubber band or wrap a shallow strip of card around the arm base – anything that will act as a spacer – it does not need to be machined sleeve.

Armboard Thickness: Once the arm is inserted through this hole, you secure it with a large nut under the armboard which clamps it in position. The armboard can be any thickness up to 25mm for this to work.

* You need not worry about VTA for Encounter arms and above as they have integral VTA adjustment.

* Arms below Encounter use VTA adjustment on the arm mounting thread itself so arm boards need to be around 20mm or less to allow adjustment.

The distance from the centre of the armhole to the centre of the platter spindle needs to be 222mm plus or minus 1mm. The arms can rotate to be clamped at any angle. The effective length of the arm from its mounting hole centre to the cartridge end of the arm is 240mm. The arm protrusion from the pivot point to the rear is 50mm to the end of the counterweight stub.

For Encounter Arms and Above – If the top of the armboard is around 24mm below the top of the platter then the arm will be at its lowest position for tracking a normal cartridge (17mm body height) and can be raised by a further 14mm

For 12-inch Arms Only – Centre of 23mm – 25mm diameter hole for arm mount to centre of platter spindle is 295.6mm plus or minus 1mm. The length of the arm from its mounting hole centre to the cartridge end of the arm is 309mm. The overhang from the pivot point at the rear end is 50mm to the end of the counterweight stub.

Note: Cartridge alignment is at best only ever a compromise. A cartridge is only aligned at 2 points on the record – For the remainder of positions on the record it’s out of alignment – We say this to save fretting over the last 0.5mm accuracy and give a bit of perspective. Alignment makes an audible difference but on the scale of other parameters, it’s really not a lot.

For Linn style arm mounts (211mm effective length arms) – We offer predrilled arm-boards for fitting our standard arms (221mm effective length) to the Linn LP12. Alternatively, we offer our arms with Linn geometry (211mm effective length) and Linn style 3 bolt base mount. This allows our arms to work as a simple drop-in replacement for all Linn arms and those which follow this geometry.

If you have a Linn LP12 turntable with a Linn arm then the armhole on your current armboard will be in the wrong position (Linn arms mount at a distance of 211mm from the platter spindle). We can supply you with a Pre-drilled armboard for the Origin Live and Rega arms at £27 – this board is identical to the Linn armboard but is missing the Linn Logo. Alternatively, you can get a blank arm-board from Linn and get it drilled. This is simple to fit.

On newer Linns the wooden corner brace has been increased in size which creates a slight foul with Standard size Origin Live and Rega arms. This is easy to rectify by removing a small semi-circle of the brace. Probably the quickest way to achieve this is to drill a series of 4mm holes as close as possible to one another in the shape of the cut out you need. Then finish off the job with a chisel.

After fitting a new arm you can find printable instructions for setting up your Linn at Linn Sondek LP12 turntable instructions.

Alternatively, you can order all Origin Live arms with “Linn geometry” – see arm options in the ordering process. This means the arm effective length is manufactured as identical to Linn geometry. We also provide a sleeve/base which allows you to fit Origin Live arms directly to your existing Linn arm board. This overcomes the problem with some later Linn decks where the armboard is integral with the sub-chassis and thus non-detachable.

For SME arm mounts – you can fit our bolt-on SME adaptor which means the arm can be fitted to any SME arm-board.

If your arm has an SME mount there is an adaptor plate available on this website which bolts to your existing mount and provides the correct hole and position for mounting Origin Live arms – see Accessories > Vinyl > Adaptors

Modifying Your Current Arm Board

If you modify your current armboard you will need to cut a hole in the board to locate the arm at the dimensions given above. This will leave you with the old hole looking unsightly. To hide this, make up a large circular plate washer of black card, aluminium or other material and glue this to the armboard – the spacing washers we supply with a new arm have an outside diameter of 48mm and will normally fulfil this function for most situations (the thickness of the washer is 1.5mm or 4mm). The advantage of glueing the washer to the armboard is that it also locates the arm in the correct position.

Arm Heights

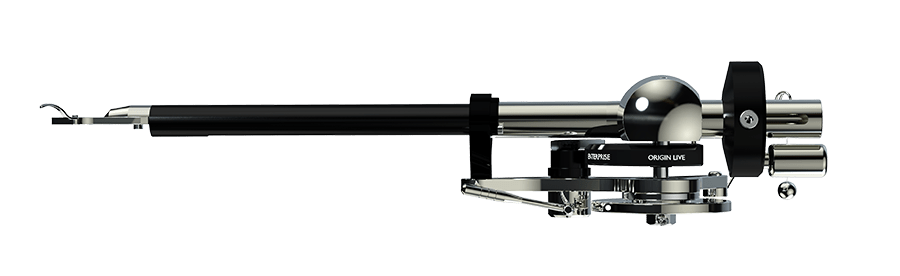

For Enterprise to Renown

Min | Max height between the top of armboard and underside of headshell is 40mm to 55mm (i.e 15mm upward adjustment)

For Encounter to Conqueror arms

Min | Max height between the top of armboard and underside of headshell is 39mm to 54mm (i.e 15mm upward adjustment)

For Alliance to Zephyr

When fitted to a 4mm thick armboard – The height between the top of the armboard and the underside of the headshell is 43mm(i.e 30mm upward adjustment). For every 1mm extra thickness of the armboard deduct 1mm from upward adjustment (30mm).

Cartridge heights normally vary from 15mm to 18mm with 17mm being the average

People often ask whether a certain cartridge will match a certain Origin Live arm. In short, the whole issue of cartridge matching and compliance is irrelevant for our arms – All our arm models track every cartridge with ease (no exceptions) and handle high energy levels with equal ease.15 years of people mounting all types and brands of the cartridge (even Deccas – the hardest to track cartridge) have taught us this. Users attest that Origin Live arms are entirely at home with Dynavector, Kuoetsu, Lyra, Benz and any other brand you care to name.

Origin Live arms are probably unique in this aspect due to various damping tricks and handling of inertia. These overcome the problems which plague other arms.

Yes, compliance matching can help badly behaved arms but with a well-designed arm, it’s of very low significance and is best ignored.

You would be forgiven for thinking the difference in sound quality between the best tonearms and others is fairly minor – after all they look fairly similar so what could possibly make any real difference?

In addition, it seems that your cartridge is at the business end of things, so the advice is “invest in a good cartridge and great sound will naturally follow”.

However intuition is not always reliable and an alternative view of things offers breakthroughs which are otherwise unachievable. This article explains why improving your tonearm will yield results out of all proportion to general expectations.

The truth is that popular tonearms seriously limit the performance of cartridges. We will examine the reasons for this in detail later. It follows that upgrading to a better tonearm will massively increase your cartridge performance and overall sound quality. Not only this but the best tonearms have the added benefits of :

Significant financial savings in the long term

Your record collection will last longer

Feedback from hundreds of e-mails testifies that a wise tonearm choice is an investment that really works. Later we examine the reasons why this long-held view of system hierarchy proves true.

In fact, this tonearm-table combo is one of the finest performers I’ve heard at any price…but regardless of price, this is one of the truly special products I’ve reviewed in the past 18 years.

Michael Fremmer – Stereophile Magazine

The biggest improvement I’ve made in 25 years of listening to music and lots of exchanges of Hi-Fi stuff…breathtaking, big new level. It’s like coming to Nirvana.

Ferdinand Ro

The most addictive product I’ve ever heard.

Audio 10 Magazine on the Conqueror tonearm

When it comes to upgrading an arm, it’s helpful to know the return on investment. One method of quantifying improvement is to look at the pricing of cartridges. Trials show that your cartridge performance can be increased to the level of one costing up to 70 times as much – the tonearm being the only difference. This claim is staggering but backed by a wealth of evidence.

For example, 25 years ago, when all serious audio systems were vinyl based, reviewers went to great lengths to establish the hierarchy of components within a system. One test took a cheap £20 AT95E cartridge, versus an expensive £500 cartridge. The only difference being the cheaper cartridge residing in a better tonearm. With utter astonishment, the £20 cartridge sounded significantly better than the £500 one! This translates to the cartridge performing at over 25 times its value!

Another example of a hierarchy is related by a German Hi-Fi shop owner hosting an evening for 40 clients. He compared a cheap £100 Denon 103 cartridge with a well respected £2500 cartridge. Again, the only difference being the cheaper cartridge in a better tonearm. Sure enough, the cheaper cartridge won by a jaw-dropping extent.

It’s worth mentioning that this wasn’t a poor arm in the ring with a good arm. Rather it was between some of the best tonearms — the highly respected Origin Live Silver arm against the Conqueror tonearm, much higher in the range. For perspective, the lesser Silver arm, was reviewed as “probably the best arm in the world”, when it first entered the market in 2002. We are looking here at an extraordinarily good arm, versus an absolutely top-flight arm. Furthermore, the “best tonearm” statement on the Silver (£600 at the time) was no wild statement made by a newbie reviewer, but a well established Hi-Fi magazine Editor with years of experience of SMEVs, Linn Ekos, Naim Aros, tri-planar, Grahams and a host of other high-end arms.

Due to their exceptional performance, even the more affordable Origin Live arms will replace much more expensive arms by other brands and still give the results mentioned above or your money back. This is not a difficult upgrade to carry out as our arms are exceptionally easy to fit and set up.

Musical Values Need to be True to Life

Origin Live tonearms are designed on the belief that equipment should be outstandingly enjoyable to listen to, and as close to the original sound as possible. This may sound obvious, but there are some who are so fixated on isolated facets of sound like deep bass or excessive detail that they lose sight of the big picture – customers are told they need their ears retraining if they don’t like what they hear. To us, this is nonsense, if the music produced is not enjoyable, then the design is fundamentally flawed.

Our tonearms have steadily earned a reputation for being the best at a musical performance. Musicality has a lot to do with the way our brains process and enjoy music. Music is like watching a group of dancers on stage. If they all perform in unison then the effect is brilliant. Conversely, if they are out of time with each other and not co-ordinated, the effect is spoilt! In much the same way, some equipment can produce a simple strand of music well enough but when more instruments kick in the timing of the bass may seem to lag behind and lack integration with the overall sound. Notable among many other common problems are overblown bass, insufficient bass or excessive treble which leads to listener fatigue.

The Unrealized Truth About Tonearm Structure

It’s natural to desire an explanation for what lies behind the spectacular transformation of cartridge performance. Firstly, your cartridge stylus generates vibration which causes your tonearm to bend and vibrate at a microscopic but measurable level. This has important repercussions.

A helpful analogy is to think of a gauge used in engineering to measure 1/1000ths of an mm. These need to be rigidly mounted to measure accurately. Imagine putting one of these on the end of a thin fishing rod and waggling it. No matter how accurate the gauge (your cartridge), its accuracy would be invalidated by the movement. This may seem extreme but it illustrates precisely why tonearm behaviour makes all the difference. Your cartridge is constantly “measuring” the undulations of the record groove at levels well below 1/1000th of an mm. If the surface it’s mounted on is unstable and moving then it cannot do its job properly.

Another analogy is that using a poor tonearm is like expecting to view an object clearly through a powerful 100X optical microscope, whilst holding the microscope with a trembling hand! Your cartridge amplifies vibration not 100 times, but a colossal 8000 times. How well does it need to be held is the all-important question? The best tonearms reduce “tremble” far more than underperformers.

How Stable is The Hold On Your Cartridge?

You cannot see tonearm vibration so nobody gets alarmed. However, this does not mean it’s not happening – big time! After all, neither can you see your stylus vibrating as it generates the audio signal for your music.

Conversely seeing the movements of your tonearm as it tracks the record leads to imagining it’s bearings must be of supreme importance. Tonearm marketing often plays to this assumption, proposing that highly specified bearings with interference fits will deliver exemplary performance. These assumptions are partially correct but shift attention away from structural vibration which is actually much more significant in terms of sound quality. A survey we conducted with over 1000 audio enthusiasts, gave the result that 82% thought bearings affected tonearm performance more than the armtube structure.

Of course, an inadequate bearing will kill performance, and yes, we research bearings very carefully, but overwhelmingly, testing shows the arm-tube to have the most influence on performance. We shall attempt to illustrate why the tube “micro-vibrates” and how this disrupts the proper working of your cartridge.

Micro-vibration is similar to electricity or sound waves. You know these things really exist because you see or hear their effects. We can also picture Micro-vibration. For example, if you hit a long tubular railing, you can hear it resonating even though you cannot see it moving. If you sit in an aeroplane, you can feel the engine causing the whole structure to vibrate but again you cannot see the movement.

These illustrations draw attention to the fact that just because you can’t see a physical movement does not mean it’s not happening. Contrasting this, you can see your tonearm physically moving up and down when playing. Just be aware that in reality, these low-frequency arm movements are of minor significance compared to the constant vibrations which intrude on the frequencies your cartridge operates at.

Forces Impacting Our stylus

As your stylus travels down the undulations in a record groove, the accelerations and dynamic forces it experiences are calculated to reach a staggering 8 tons per square inch. The tip can move back and forth up to 30,000 times per second! To visualize the micro-vibration generated by this speed of movement, imagine a miniature man with a sledgehammer standing in front of the stylus and banging it from side to side with all his might. This energy is injected into your tonearm and as this occurs, things get very complex for engineers who understand the implications (not all do).

One powerful illustration I have witnessed on unseen vibration is the effect of explosive underwater shock on ships. When a mine explodes under a vessel, the hull structure “ripples” at very high speed. So fast that even 10mm bolts holding fittings snap under the extreme acceleration. The fittings are propelled into space at speeds of up to 400mph (600kmh). This transforms the interiors into lethal areas full of bolts and fittings, flying around like shrapnel – nothing survives, but the hull structure can remain largely intact.

Only fast frame photography at 800 frames per second, shows why these fittings fly off with lethal consequences. You would not see this ripple, as the eye can only see the equivalent of 60 frames per second, but it’s there – revealed by slow-motion replay, of the high speed bending that “flicks” off objects attached to the structure.

In the same way, your arm tube structure is subject to a continuous series of “shock waves” which you do not see. The resulting structural “ripples” affect the stability of your cartridge to a critical extent and this is what we will discuss next.

Unwanted Cartridge Motion Caused by Flexing in Micro-vibration

Even the best tonearms move, flex, ripple and resonate, in micro-vibration – In combination, these movements are extremely complex but must be reduced if high performance is to be achieved. I have heard turntable and tonearm manufacturers talking about the mechanics of analogue play as being no more than O-level physics – it’s not surprising that this lack of understanding and respect for the intricacies of vibration leads to products that seriously under-perform. Merely thinking in terms of zero play bearings, resonant frequencies, compliance and so on are similar to trying to design an aeroplane just knowing the laws of gravity whilst being ignorant of the laws of aerodynamics.

6 Degrees of Movement Experienced in Vibration

To illustrate cartridge stability, imagine a ship in a storm, the movement can be broken down into 6 degrees of motion namely – 3 rotational axis to give roll, pitch, and yaw, along with 3 linear movements, heave, surge and sway. All these movements occur with a cartridge – this may seem far fetched, but we are talking about very minute movements, amplified to such an extent that it is almost impossible to get our heads around.

Ship Movements Illustrate Unwanted Cartridge Motion

Because of these movements, it’s easy to see why tonearm design has to be of the highest order. When tonearms cause cartridges to under-perform, the results are loss of clarity and almost every other vice imaginable. For example, some arms can make the sound “dull and lifeless” whilst others have a tendency to make it “harsh and uncontrolled”. Improving your arm will enable your cartridge to sing in ways that you would not believe possible. In fact, the true extent of the sublime improvements wrought after changing to an Origin Live arm always seems to come as a delightful surprise to people.

Music lovers tell us that after years of searching, they finally find the solution to many flaws that had previously bothered them or that they were not even aware existed with their old arms. These are owners of respected and expensive arms. The good news is that you do not need to spend a fortune to achieve true high-end performance. Our best tonearms are renowned for their extraordinary high performance and shocking value for money.

How Are The Best Tonearms Designed?

Build quality with underlying design flaws is a waste of money and does not deliver real results however pretty it may be looking at and admire.

For example, aside bias mechanism with a beautifully engraved spring dial may look to have better build quality than the thread and falling weight that we use – the problem is that the spring mechanism invariably “rattles” in micro-vibration and the degradation is clearly audible when amplified 8000 times. We have exercised a steady refusal to be seduced or pander to these flawed values which mitigate against true sound quality. Small details like this may seem insignificant on their own, but a multitude of similar instances soon add up and ultimately a very significant performance lead is built up.

The exact methods we use to model the best tonearm behaviour and optimize design always derives from real-world experimentation and observation. Many of our major innovations are not found through techniques like FFA (Fast Fourier Analysis – which can only ever be as good as the programming assumptions). Rather they have been discovered by pure accident because they are so counter-intuitive.

Comparing Technical Performance

Tonearms appear quite similar, but in fact, nothing could be further from the truth. There are various schools of thought on how to tackle the design challenges presented. The most popular theory is that energy is best absorbed by damping, so there are manufacturers who go to great lengths to “prove” superior performance by using instruments to measure and compare resonant frequencies.

The big problem with this approach is that it’s only one aspect of a complex picture. Technical measurements have proved time and again to have their limitations. Suffice to say, there are many well-known examples in Audio history from CDs with low distortion figures, to speakers with a perfect frequency response that sound terrible.

The fact is that excessive damping is often applied to solve problems that should not exist. Heavily damped arms may measure fantastically but sound dull and lifeless. They also tend to compress and kill the delicate decay of notes – this is sometimes mistaken for “control” or an “analytical” sound.

Questions To Ask About Measurement Data

We noticed that accelerometer tests (which measure arm movement frequency) conducted on tonearms which gave “better” technical figures did not always give better results in subjective listening tests. So what is going on? To oversimplify a complex subject is always dangerous and it should be pointed out that the interpretation of accelerometer data ignores four very important aspects:

a) Actual deflection and angular rotation of the tonearm in vibration – This measurement is in our view more important than resonant frequency figures. In other words, the size of the movement is more important than the frequency it’s moving. For example, if the movement was infinitesimally small the frequency would be completely irrelevant. In an effort to increase stiffness some tonearm manufacturers have used very large diameter tubes. These may be stiff for very low frequencies but they will suffer from vibration ripple within the very thin walls of the tube.

b) The ” recovery speed” (the speed to get back to correct position) – e.g a good longbow, recovers very quickly to its original shape when firing an arrow, but a soft wood bow is slow and ineffective because it is more damped. As a rule, the higher the damping, the slower the recovery. You actually need the correct balance of both high-speed recovery and damping which is why we test exhaustively to achieve this.

c) The speed of energy transmission and the locations at which damping or energy loss occurs is not measured. These factors introduce timing issues and energy reflections.

d) The measurements given are usually on only one axis which leaves 5 other movements totally unmeasured. Unfortunately, one axis measurements do not necessarily indicate what the rest are like.

The Founder of Origin Live is a fully qualified chartered engineer with experience in complex structural analysis. It was his conclusion that current models for tonearm behaviour are oversimplified to the extent of being plain misleading. One example of this is how compliance formulas that are supposed to match cartridges to the effective mass of tonearms bear so little relation to practical outcomes. This matters because you need an accurate theoretical model to determine the best tonearm design.

Intensive Research and Innovative Thinking

The design of our tonearms is the key to their performance. Over 25 years of continuous development has gone into these arms. However, it’s the “outside the box” thinking, which make them special. Origin Live arms are extremely innovative, not only in concept but also in the choice of superior build materials. Wherever possible high-grade alloys are included. These alloys are expensive to machine and finish but the results are so worthwhile in terms of performance.

Most arms look great on the outside so it is easy to miss the massive hidden differences. With an Origin Live arm, you can be sure that it’s not just a matter of high-grade components but far more importantly, you have a design that really delivers in terms of performance.

Tonearm Overall Design Philosophy

Much of the design philosophy behind Origin Live tonearms is discussed in our web page Aspirational design which is an important introduction.

Tonearm Design Specifics

The specific design attributes of our tonearms are described in detail on the web page Tonearm design specifics.

High Strength Components

Your cartridge needs to be held with rock-like solidity if it is to accurately extract the microscopic information contained within your record grooves. In strategic components, rigidity is essential to reduce microscopic bending and “give” in the tonearm structure. The exact reasons why this is so critical go far beyond superficial explanations such as reducing movement or resonance. The truth is little understood and would require a book to explain due to technical complexities.

Soft alloy castings and carbon fibre tubes (using fishing rod technology) are commonly used in tonearms but are wholly inadequate for high-grade performance. Origin Live arms avoid these cheap alternatives and as you might expect the music benefits immensely from the improved rigidity. Gone is the soft, woolly, haziness and muddle that so many arms are responsible for producing. Instead, notes have a greater impact, dynamics, speed. This gives our arms their outstanding reputation for realism.

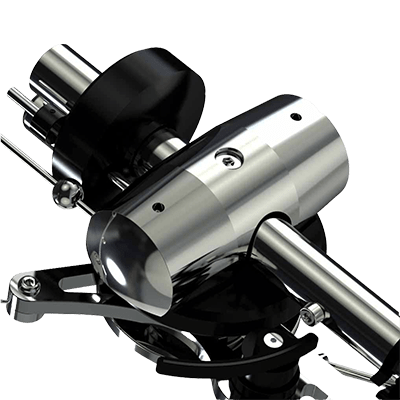

Ultra-low Friction Bearings

All bearings in our arms function with exceptionally low friction. This aspect is one of the reasons behind the phenomenal tracking ability of our tonearms which defy compliance formulas. Subjectively it also results in a far more transparent sound. This achievement is due to intensive research resulting in all bearings being manufactured to our own exacting specifications.

Floating Bearings

Unlike most arms, we “float” the bearings so they have minimal contact with their housing. This seems to counteract the principle of rigidity but works because isolation becomes the over-riding factor at this point. This is a prime example of where untested adherence to a single misunderstood principle is not the best answer.

The advantage of improved decoupling is a considerable reduction in noise produced by the equipment.

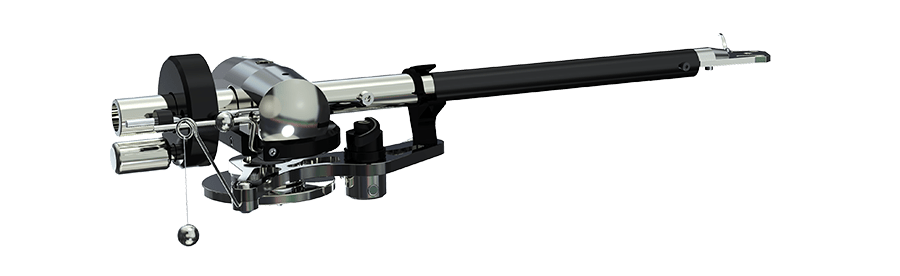

Dual Pivot Bearings

The Encounter arm and above, employ dual-pivot bearings. There are around 4 other high-end arms in the world that employ this technique. All came out around the same time to combine the virtues of standard gimbal bearings with the strengths of Uni-pivot designs. Read More

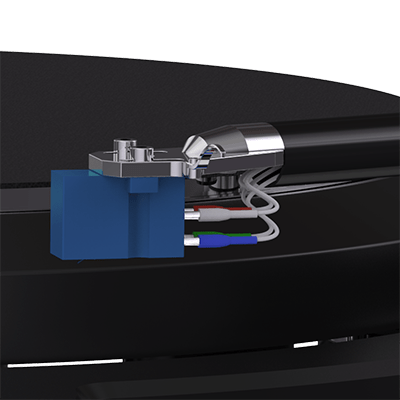

Internal High-grade Copper Litz Wire

Litz wire is renowned for its transparency and lack of grain. We use high-grade copper Litz wire manufactured to our own specification. This is much harder and more costly to work with than conventional wires.

Cartridge tags are copper beryllium for high conductivity. They are then plated with Gold, Silver or Rhodium depending on the grade of the arm.

Internal wires for higher grade arms are upgraded to Silver Hybrid wire. This is a proprietary design that dramatically improves performance whilst avoiding the brightness sometimes associated with Silver.

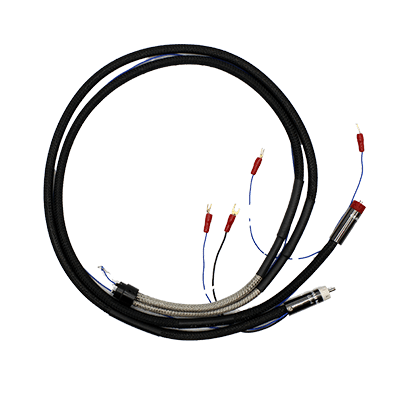

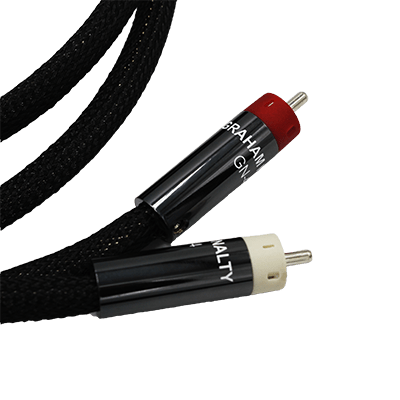

External Wiring

External wiring comes in a number of grades. You can find the grade for each arm on the specification pages.

Standard Cable: This is a commonly used tonearm wire which although thin and unimpressive in appearance is well designed and performs well. Some make the mistake of using conventional, expensive interconnect wire for tonearm cable. The reason this seldom improves performance is that tonearms must handle signal levels that are around 1000 times less than CD or streamers etc. This needs a different design approach.

Upgrade Cable: Called “upgrade cable” because it upgrades the cable on high-end arms. This high purity copper cable is cryogenically treated and possesses many of the attributes needed for good low-level signal conduction. Carefully researched and great value for money.

Silver Hybrid Cable: After years of research we finally came up with a huge advance on tonearm cable performance. Silver hybrid, as the name suggests is a combination of copper and silver wiring. This highly specified combination was tried against a leading £1000 tonearm cable (better than some at £3000) and found to be a long way ahead.

The sound delivered has all the transparency and purity you expect from Silver but without the slight tonal lift and edginess. You can be confident that this is a supremely capable performer.

Silver Hybrid-S Cable: This is a specially treated version of Silver Hybrid Cable with increased transparency and cohesion. The treatment method is proprietary and unique.

Connector RCA plugs

The phono plugs fitted to our cables have a surprisingly audible influence and are fitted in 3 grades

- Nickle plated brass, moulded RCA Phono Plugs

- Gold plated Brass, clamping RCA Phono Plugs: To ensure a secure joint, these RCA use a twist-action to clamp them hard onto your amplifier Sockets. This improves performance and reduces noise.

- Black Rhodium RCA Phono Plugs These single point contact RCA plugs are Rhodium plated for improved current flow and minimal eddy currents. Rhodium may not possess the highest conductivity but this is outweighed by its unsurpassed surface smoothness which enhances performance at joints. They are simply the best sounding high-end performance plug we’ve heard.

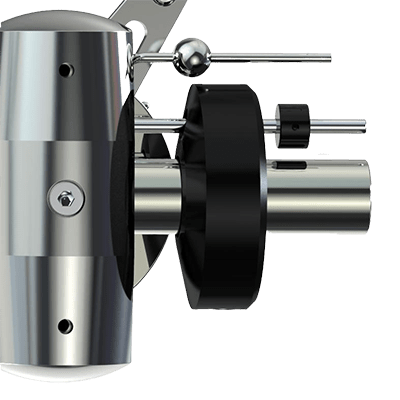

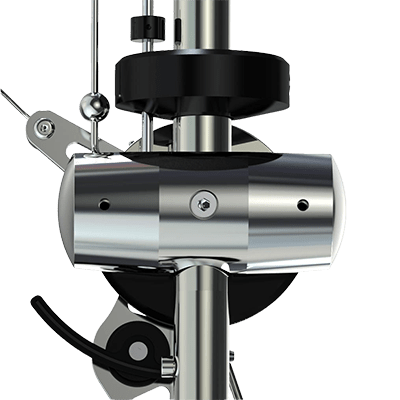

Integral VTA adjustment

Cartridge “Vertical Tracking Angle (VTA) is adjusted by raising or lowering the rear end of the tonearm. This is an important adjustment to get the most from many cartridges and is included on all Origin Live arms. Our VTA adjustment is infinitely variable, calibrated and easily repeatable with precision.

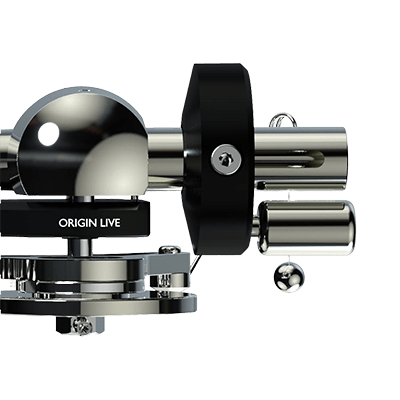

Tracking Force Adjustment

The downforce on the cartridge (tracking force) is adjusted by positioning the counterweight using a secure mounting. We avoid common methods which use loose threads, magnets or springs which have the drawback of feeding resonance into the structure (which affects the cartridge).

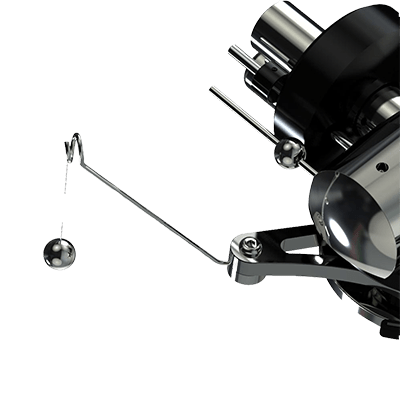

Side Bias Adjustment

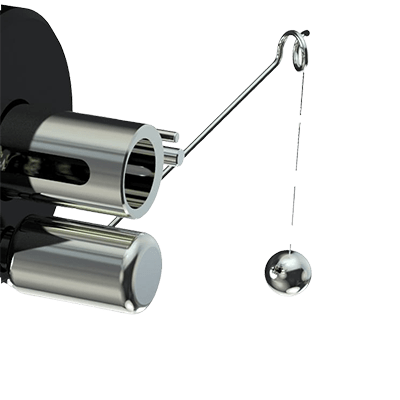

Your cartridge generates an offset friction force as it slides through the record grooves. The tendency is for the arm to force the cartridge stylus onto the inner wall of the groove ( not the outer wall as some mistakenly think). To counteract this force using what is known as “side bias force” ensures that the cartridge plays evenly within the groove and reduces wear of both record and stylus.

The method of applying side bias affects performance. These include:

a) Spring dials

b) Magnet dials or slides

c) Falling levers

d) Varying the leverage using a thread and falling weight.

Research has concluded that d) is significantly superior in terms of sound quality to the other 3 for reasons explained in a later section “What makes a better arm”. For this reason, all our tonearms use method d).

In the same way, great singers have better voices, all materials resonate differently and have a “voice” in micro-vibration. There is an argument that says the ideal material is totally dead, but this oversimplification ignores the fact that to absorb energy, the material has to vibrate. The argument also omits to consider that if a material is too soft (like a sponge to take an extreme example) then it will lack rigidity. Conversely, if a material is too hard then it reflects energy which is disastrous. Because all these factors conflict with one another it renders correct material choice much more complex than many imagine.

The nature of mechanical playback means that every material chosen plays a role in performance. Specifications and theory can only play a limited role here. If pure measurements were the answer, you could use a computer to judge the talent of singers on shows like the Voice or the X-factor. The problem is that any measurement system can only measure what it’s programmed to. Understanding the physics of what makes one voice more preferable to another would probably take more than a lifetime. For this reason, we conduct hundreds of listening tests to determine the best choices.

Origin Live pay obsessive attention to the types of material used throughout the construction of turntables. This is one reason our Platter Mat (offered as an accessory) upgrades 99% of turntables on the market. The same is true for our turntable belts and oil, both of which receive remarkable reviews from satisfied clients. These may seem trivial examples but they indicate a fanatical thoroughness in research that extends to much more important areas in our turntables.

The Priority of Low-Level Signal Purity

It is difficult to appreciate why the mechanical integrity of a tonearm should have such an enormous influence on the performance of your system. The first step is to realize that the mechanical movements and electrical signals generated by your cartridge are extremely small – beyond imagination. The electrical signals generated by mechanical movement are amplified thousands of times to produce sound through your loudspeaker.

It follows that the slightest source of unwanted vibration and resonance is magnified to exactly the same extent as movements intended to create the correct signal. Not only can unwanted vibration introduce colouration, but this vibration also affects the cantilever movement to cause distortion. It’s the elimination of this spurious vibration that results in the large differences that exist between mediocre and high end arms.

The Cause of Unwanted Vibration

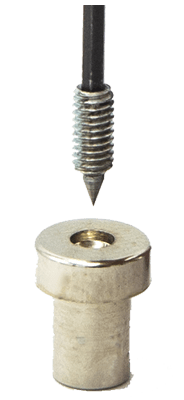

As the cartridge stylus negotiates its tortuous way through your record grooves it undergoes forces measured in tons per sq. inch. This sends shock waves down the arm tube. What happens to these shock-waves normally? Some of the energy is transmitted down into the deck, but much of it meets the counterweight structure and is reflected back down the arm tube to the cartridge. This is highly detrimental for good sound quality due to the aforementioned facts. There is a secondary reason why the rear end of the arm is an extremely critical area. The counterweight represents by far the highest moving mass in the arm and affects an arm’s performance in ways that are hard to imagine. The counterweight is excited into resonance by the motion of the arm. This means that it should be decoupled and yet also remain rigid to the arm (to avoid introducing other problems). The beauty of the Origin Live designs is that the rear end of the arm acts as a shock absorber. For mechanical waves travelling down the arm from the cartridge and the rear end acts to de-couple the counterweight, whilst maintaining rigidity.

Proven Design Principles

Origin Live’s first work on tonearms involved removing the rear-end stub of Rega tonearms and upgrading them with a replacement design. Rega rear end stubs are screwed into the end of the arm – this leaves much room for improvement! Origin Live replace the old stub with a new stub. The new stub is torqued onto the arm by a thin high tensile bolt. The new stub is also designed for optimum decoupling whilst maintaining more rigidity in micro flexure than the original. This change also allows the counterweight to be rigidly clamped onto the stub using an Allen bolt. An unmodified arm should not have the counterweight rigidly coupled in this way, due to the old vibration characteristics of the standard arm/rear stub joint. This ingenious modification elevates a good arm into the same league as the super arms and at an insignificant outlay.

De-coupling The Armtube

To give an example of the way that Origin Live “break the mould” with design, you only have to observe the “floated bearing” philosophy that is employed in the tonearms. Origin Live bearings are highly specified to suit tonearms – however the bearing houses are deliberately not machined to a tight tolerance as this degrades up the sound to an intolerable degree. We have found that tightly held bearings are not beneficial but this is easily confused with “bearing play”. There are very strong technical arguments to suggest that tightly coupling the arm to the deck via tight bearings is detrimental in the light of listening tests. These confirm that once you house the bearings outside the arm tube, it is best to “float” them rather than “grip” them in a tight fitting housing. People hypothesise about bearing chatter, etc. – maybe this is the case with high resonance arm-tubes and lower quality bearings. However listening soon shows up that there is absolutely no bearing chatter in any of our arms – in fact, resonance in our arms is so minimal that it’s extremely difficult to measure in terms of amplitude or deflection.

Minimising Ripple Effects

Another factor that indicates “floating” the arm tube to be a good idea is that uni-pivots and knife-edge bearings work on this principle. Vibration transmits through the surface which supports the tonearm in various ways. Most significant is “rippling” – not just a simple 1 or 2-dimensional movement as some imagine. Ripple exerts twist or angular force into the structure.

The mechanism of ripple is seen dramatically with very fast frame photography taken inside ships undergoing underwater explosive shock. When a mine explodes under a ship, the inside becomes a death-trap of flying fittings that have become detached due to the underwater shock wave. Anything attached to a side wall or part of the ship structure detaches at speeds of up to 600Km/hour. The reason this happens is due to the shock waves setting up ripple in the ship structure and side walls.

In the micro-vibration that occurs in the analogue replay, ripple effects are very important. Uni-pivots are rigidly grounded in one sense but decoupled completely from ripple effects. However (and it is a big “however”) they cannot hold the cartridge well against torsion exerted by bass notes. Widely spaced conventional bearings reduce ripple effects as do floated bearings. However, they have the added benefit of holding the cartridge rigidly, resulting in more dynamic bass performance.

Low Friction Bearings

The Silver tonearm and upwards use special low friction bearings that improve in the specification. Long and intensive research has been invested in bearing design as it plays a very significant role in sound quality. The influence of bearing friction is surprising and can only be put down to the fact that it not only allows improved tonearm tracking but more importantly minimises environmental vibration from affecting the arm. This effect can be likened to putting the tonearm on ice. The ice can ripple but due to low friction and inertia, the tonearm is affected much less in terms of vibration and motion.

Excellent Conductivity

The quality of cable required to transmit the extremely low level of signals generated by cartridges needs to be of the highest calibre. Origin Live has invested exhaustive research into this critical area over many years and have developed the best sounding cables possible.

Dual Pivot Design on Higher Arms In The Range

Dual pivot combines the virtues of ultra-low friction uni-pivots with the stability of conventional gimbal bearings without any of the drawbacks. The pivot points are made from a special grade of Tungsten which sits in hardened steel cups. Jewelled bearings were rejected as they are prone to shatter and proved too fragile with no real sonic advantages. The bearings controlling horizontal movement are a low friction design specified by Origin Live.

Carbon Hybrid Tube (higher range arms only)

The armtube uses a special carbon fibre construction combined with Ebony and expensive metal alloys. Carbon fibre is both strong and inert. However, even the most inert materials still have “tone”, and the only way to further reduce resonance is to combine other materials into the mix.

This principle is best illustrated by the legendary “Stradivarius” violin. Stradivarius found that particular types of wood in special combinations made all the difference in the world to the sound produced. The same principles of endless testing with pitch-perfect hearing has been conducted over many years to refine Origin Live arm designs – the only difference being that resonance is being eliminated rather than created.

VTA Adjustment

All arms include built in VTA adjustment – arms from Encounter and upwards have the advantage that this adjustment can be carried out from on top of the armboard. Lower arms in the range require accessing the underside of the armboard to tighten the clamping nut

Azimuth Adjustment

Correct azimuth is set at the factory using highly accurate jigs. However, cartridges are not always manufactured to super fine tolerances and therefore some people like the ability to adjust azimuth themselves. We provide this facility on all our upper arms from Encounter and above.

Tonearm Effective Mass and Cartridge Matching

To minimise vibration it is often recommended to match the tonearm effective mass to the stylus compliance. However, in practice, matching the arm effective mass is nowhere near as important as very low resonance and structural integrity within the arm itself. Yes, compliance matching can help in badly behaved arms but with a well-designed arm, it’s of such low significance that it can be ignored.

If you wish to see details such as size measurements, weights and a breakdown of features please use links below.

Origin Live 9.5″ (239mm) Standard Tonearm Specifications (same as Rega Geometry) >

Origin Live 9″ (229mm) Linn Geometry Tonearm Specifications >

Origin Live 10″ (254mm) Tonearm Specifications >

Origin Live 12″(309mm) Tonearm Specifications >

Print Tonearm Specifications

For information on fitting an Origin Live tonearm, See Tonearm fitting >

KEY PARAMETERS FOR ALL ARMS

- Effective Length 239mm (9 inch Version), 254mm (10 inch Version), 309mm (12 Inch Version)

- Effective Mass: Varies according to model – See specifications (links above).

- Arm mount adaptors are available to fit many decks – See fitting guidance.

- Tracking Force set by Counterweight position – no springs.

- Side Bias set by falling weight on the thread for ultra-low friction.

- VTA adjuster enables infinitely variable height adjustment in easily repeatable increments.

To order an Origin Live arm and see the various options and extras available, simply press the “Add to Cart” button. This takes you to the order page which shows a number of options and extras. Below is a summary of the more important options available.

Effective Length and Fitting Options

Our Standard arms are 9.5 inches (240mm) effective in length. These fit the following decks:

- All Origin Live decks

- All Rega decks and any deck with a Rega arm mount

- All turntables with an SME mount – you can order our SME adaptor plate to enable this (see options on the order page).

- All Technics 1200 or 1210 series decks – you can order our Technics armboard to enable this (see options on the order page).

We recommend using our standard 9.5 or 12-inch length arms whenever possible even if it means asking your turntable manufacturer for a Rega arm mount. You may also be able to adapt your current armboard to fit the 9.5-inch arms. See Fitting guidance. The reason for this recommendation is that if you should ever wish to upgrade your deck to an Origin Live turntable then the arm will fit perfectly. Secondly, the arm has a wider demand and usually maintains a higher value.

There are instances where it is difficult to fit the 9.5-inch arms so by popular demand we also offer different arm lengths and geometry to enable fitting to a large variety of other brand turntables. These are listed on the ordering page for every arm.

- 9-inch length (229mm) with Linn effective arm length and geometry with base mount to fit your existing Linn armboard. This arm version will install directly on your Linn as a drop-in replacement for all Linn Arms > Read More

- 10-inch arm length option (will not fit Origin Live decks)

- 12-inch arm length option (fits Origin Live decks)

Cable Options

You will see these various options below offered on the ordering page for each arm – You need to click the “Add To Cart” button of a tonearm page to view these, as options vary slightly between arms.

Internal and external wiring with RCA phono plugs are included in all our tonearms. The comparison chart above will tell you the grade used in each arm.

We offer additional internal and external cable upgrade options. These come in various grades which you will see on the tonearm ordering page. A full description of some of these upgrades is given on the link tonearm cable upgrades.

If you have a Linn LP12 or similar turntable we highly recommend ordering your arm with the right angle 5 Din Pin option. This is useful because there is often not a lot of room to bend the cable to clear the baseboard.

Of all the cable options the Silver Hybrid cable makes by far the most difference, as it possesses extremely high performance against cables costing over 6 times as much.

All Origin Live’s product imagery is representative only including but not limited to the photos and/or renders on the website and in brochures.

The expense of high-quality photos and renders is extremely high. Updating all imagery for minor detail changes only results in higher prices, which we feel is not in the best interest of our clients.

For example, we could be taken to task for changing a bolt finish from silver to black etc. To update the Tonearm Range for this detail would demand thousands of pounds.

Our brochures normally state “The manufacturer reserves the right to change specifications without notice in the interests of our policy for continuous improvement” – this applies to the website in all respects.

You can fit Origin Live arms to most decks without too much problem. We outline the various scenarios below.

Fitting to a Rega Arm Mount

This is the simplest case so we put it first. Rega arms and their modified versions (i.e Michell, NAD etc) are easy to replace with an Origin Live arm. All standard length (239mm) Origin Live arms will fit directly into all standard Rega armboard mounts. No additional holes are needed, no modifications, no extra fittings, no VTA adjusters. This easy swap is down to the geometry of Origin Live arms being identical to all Rega arms.

It makes no difference if the Rega mount you have is the later 3 point mounting or earlier single hole mounting. Neither does the model number or vintage of a Rega arm make any difference.

The only question some people raise after fitting their Origin Live arm is that 3 mounting holes remain visible if the mount is the 3 point type of Rega mount. The solution to tidy up the looks is either to fill the 3 holes with dummy round head M3 Allen bolts or you can order a 1mm thick Formica black disc from us to cover the holes > see link Disc to cover 3 Rega mounting holes. Other solutions include simply cutting a cover disc from a black card or thin plastic.

Armboards & Mounting Position

Hole Diameter: You can fit Origin Live arms to any deck but sometimes your armboard may need modification or changing to a new one – (contact a dealer or the turntable manufacturer for the second option). The tonearms require a single hole in the armboard or plinth – from 23mm to 25mm in diameter (23mm is ideal for accurate fit). If the hole in your armboard is say 1mm or more oversize then all you need to do is centralize the arm in the hole. For best performance, you do not want a tight fit and so all you need to do is put a rubber band or wrap a shallow strip of card around the arm base – anything that will act as a spacer – it does not need to be machined sleeve.

Armboard Thickness: Once the arm is inserted through this hole, you secure it with a large nut under the armboard which clamps it in position. The armboard can be any thickness up to 25mm for this to work.

* You need not worry about VTA for Encounter arms and above as they have integral VTA adjustment.

* Arms below Encounter use VTA adjustment on the arm mounting thread itself so arm boards need to be around 20mm or less to allow adjustment.

The distance from the centre of the armhole to the centre of the platter spindle needs to be 222mm plus or minus 1mm. The arms can rotate to be clamped at any angle. The effective length of the arm from its mounting hole centre to the cartridge end of the arm is 240mm. The arm protrusion from the pivot point to the rear is 50mm to the end of the counterweight stub.

For Encounter Arms and Above – If the top of the armboard is around 24mm below the top of the platter then the arm will be at its lowest position for tracking a normal cartridge (17mm body height) and can be raised by a further 14mm

For 12-inch Arms Only – Centre of 23mm – 25mm diameter hole for arm mount to centre of platter spindle is 295.6mm plus or minus 1mm. The length of the arm from its mounting hole centre to the cartridge end of the arm is 309mm. The overhang from the pivot point at the rear end is 50mm to the end of the counterweight stub.

Note: Cartridge alignment is at best only ever a compromise. A cartridge is only aligned at 2 points on the record – For the remainder of positions on the record it’s out of alignment – We say this to save fretting over the last 0.5mm accuracy and give a bit of perspective. Alignment makes an audible difference but on the scale of other parameters, it’s really not a lot.

Fitting to the Linn LP12

If you have a Linn LP12 turntable with a Linn arm then the armhole on your current armboard will be in the wrong position (Linn arms mount at a distance of 211mm from the platter spindle). We can supply you with a Pre-drilled armboard for the Origin Live and Rega arms at £27 – this board is identical to the Linn armboard but is missing the Linn Logo. Alternatively, you can get a blank arm-board from Linn and get it drilled. This is simple to fit.

On newer Linns the wooden corner brace has been increased in size which creates a slight foul with Standard size Origin Live and Rega arms. This is easy to rectify by removing a small semi-circle of the brace. Probably the quickest way to achieve this is to drill a series of 4mm holes as close as possible to one another in the shape of the cut out you need. Then finish off the job with a chisel.

After fitting a new arm you can find printable instructions for setting up your Linn at Linn Sondek LP12 turntable instructions.

Alternatively, you can order all Origin Live arms with “Linn geometry” – see arm options in the ordering process. This means the arm effective length is manufactured as identical to Linn geometry. We also provide a sleeve/base which allows you to fit Origin Live arms directly to your existing Linn arm board. This overcomes the problem with some later Linn decks where the armboard is integral with the sub-chassis and thus non-detachable.

Fitting to an SME mount

If your arm has an SME mount there is an adaptor plate available on this website which bolts to your existing mount and provides the correct hole and position for mounting Origin Live arms – see Accessories > Vinyl > Adaptors

Modifying Your Current Arm Board

If you modify your current armboard you will need to cut a hole in the board to locate the arm at the dimensions given above. This will leave you with the old hole looking unsightly. To hide this, make up a large circular plate washer of black card, aluminium or other material and glue this to the armboard – the spacing washers we supply with a new arm have an outside diameter of 48mm and will normally fulfil this function for most situations (the thickness of the washer is 1.5mm or 4mm). The advantage of glueing the washer to the armboard is that it also locates the arm in the correct position.

Arm Heights

For Enterprise to Renown

Min | Max height between the top of armboard and underside of headshell is 40mm to 55mm (i.e 15mm upward adjustment)

For Encounter to Conqueror arms

Min | Max height between the top of armboard and underside of headshell is 39mm to 54mm (i.e 15mm upward adjustment)

For Alliance to Zephyr

When fitted to a 4mm thick armboard – The height between the top of the armboard and the underside of the headshell is 43mm(i.e 30mm upward adjustment). For every 1mm extra thickness of the armboard deduct 1mm from upward adjustment (30mm).

Cartridge heights normally vary from 15mm to 18mm with 17mm being the average.

Last month Origin Live won the “Turntable of the Year Award” in Hi-Fi+ magazine. One reason we continue to win awards is that we pay enormous attention to details a few others consider worthy of investigation. For example, there is not much written about the design of side bias devices and even less about how they compare in sound quality.

If you care about sound quality, the type of Side Bias design is surprisingly influential. Not just for its function in keeping the cartridge central in the groove but for the degradation it causes to performance.

We’ve thoroughly investigated this area and listened to the effect of the various methods used to apply side bias.

The results verify that producing a good side bias device deserves a great deal of attention. Certainly more than some who dismiss devices such as a falling weight on a thread as “cheap”, whilst praising inferior magnetic or spring-loaded devices with nicely engraved dials.

Brilliantly engineered precision dials that control side bias within a second to a fraction of a gram, impress you with their sophistication and ease of use. They look great and breathe precision engineering. There is only a couple of unanswered tick boxes – are they really accurate and what’s the effect on sound quality? Many discover too late that great engineering is never a guarantee of sound design.

Without proper respect for the inconceivable effects of micro-vibration, it’s easy to dismiss this type of research as obsessive and insignificant. However, it’s not difficult to prove the clearly audible artefacts that whimsical side bias designs impose on sound quality. More on this later.

So before the allure of attractive dials and the illusion of precision tempts us, let’s just step back and examine first principles in more depth.

Principles of side bias

It’s commonly expected that as a tonearm tracks through the grooves it experiences an outwards force. Centrifugal force or differential friction acting on the inner and outer sides of the stylus are intuitive reasons for this misconception.

In reality, a frictional force acts tangentially to the groove. This “pull” on the arm is not in line with the arm pivot but offset and thus produces an inwards (not outwards) side force – see diagram below.

Things are far from simple but without going into detail it’s safe to summarise that the inward drag induced force is fairly consistent across the record increasing by about 18% towards the inner tracks (this is controversial as it depends on the cut of a record).

Side force is detrimental for the following reasons:

· The unequal force on the inner walls of the record groove affects the soundstage image slightly.

· It causes uneven record wear.

· The cartridge suspension is skewed out of alignment from its central sweet spot in the motor mechanism. This affects performance to a degree dependent on cartridge suspension – softer suspensions suffer badly.

A good side bias neutralises these effects by counteracting the induced inwards force with an equal and opposite outwards force. In so doing, the stylus tracks the groove centrally to produce a notably more solid and focused soundstage.

It is easy to be carried away with the marvels and speed of the advance of digital mediums. It, therefore, surprises some that highly respected audio experts will say a top-flight record player far surpasses the sound quality of all digital sources. They passionately own vinyl as their first choice in sound quality and will tell you this will remain so into the foreseeable future. They see it as the pinnacle of sound quality because it’s more natural, smoother, more coherent, and a more musical presentation than digital. In comparison, digital can often sound harsh, disjointed and a musical mess that the ear finds unattractive.

In spite of this digital has advantages and the discussion regarding format superiority has many aspects which make it a controversial area. For example at the very budget end of the market, the price for price, digital has better sound quality, convenience and availability than vinyl. However, once you get beyond £500 for a good record player, this state of affairs is reversed in terms of sound quality.

At the extreme high end, Germany’s largest Hi-Fi magazine (Audio) declared that a top turntable outperformed their reference Digital player comprehensively on EVERY aspect of music.

Technically, both Digital and Viny face challenges and neither can claim superiority on this basis. For this reason, judgements should be based on observation rather than dogma. It’s interesting that in photography, digital has still not claimed supremacy in the high end. The highest resolution cameras for producing Imax cinema film are analogue, not digital (although they use digital for lower quality productions).

Limits of This Article

Time will not permit this discussion to look at all aspects of Digital vs Analogue so we will confine ourselves to the single aspect of sound quality. This leaves out the more well known and conflicting aspects of cost, convenience, speed of access, mobility, wear, longevity, tangibility, nostalgia, retro, availability of older recordings in digital etc. There are important advantages and disadvantages in both formats and your preference will vary from others. If sound quality is important to you then the following discussion should be relevant.

Reasons For The Perception of Digital Sound Superiority

CDs first started the transition away from vinyl LPs back in 1985 promising “pure, perfect sound forever” – “no more crackles pops and hiss”. Vanishingly low distortion was quoted at 0.001% at 1kHz. What wasn’t there to love?

The proof of digital sound superiority was simple – Compare it to an average record player. Of course, most people found the CD sounded better.

The world domination of digital vs analogue became overwhelming – pockets of analogue resistance held out. Strangely those who loved the analogue sound were viewed to have a mild form of benign insanity. This was eventually to prove an infectious disorder. So much so, that there was a steady growth of those reverting to the medium and this continues to this day.

The disorder gets so bad that we regularly receive letters like “your turntable has rendered my CD player unlistenable”.

To hear that vinyl is not just subjectively preferable but also technically superior still comes as a shock to the vast majority of people whose main exposure to formats is moulded by a huge industry marketing machine.

The purpose of this article is to shed fresh light on why so many top reviewers and music lovers still prefer vinyl and will continue to do so.

Mistakes of The Past

To save repeating the mistakes of the past it’s worth understanding why many turntables hugely under-perform to the extent that many never hear what analogue is capable of. The main culprit was probably the low-quality electronics used for turntable amplification. These were often inadequate to resolve and properly amplify the very low signal levels of a turntable (over 200 times lower than CD output). As if this was not enough, the design and build of an average non-specialist turntable was not capable of high sound quality.

Why Analogue For Best Sound?

This is a complex and controversial area where not much is what it seems at face value. For example the low distortion figures of CD are fantastic at 1kHz but far from fantastic at lower frequencies where vinyl does far better. To save getting bogged down in technical aspects where even the experts disagree, we will look at observations, principles and leading arguments.

Infinite Resolution

Firstly analogue has an infinite resolution (theoretically) which digital is always attempting to reproduce using limited and finite resolution. The Universe functions on the infinite analogue resolution as seen in light waves, sound waves, water waves, atomic vibration and on it goes. The ear loves infinite resolution. Of course, it is realized that resolution is not quite infinite because of finite aspects and there are limitations such as the size of atoms ultimately.

The Ear Identifies Digital As Fake Analogue

The ear is incredibly discriminating at a sub-conscious level and prefers pure analogue without the artefacts introduced by digital conversion.

The Complexity of Converting Digital Back to Analogue

To play music, all digital sources must convert a digital signal back into an analogue one. The conversion process is fraught with issues beyond the comprehension of even the experts in this area. In fact, it took years before it was acknowledged by some that CD players sounded different from one another. It took many more years before anyone was able to prove the reasons why. Then people started noticing that digital cables sounded different. This is still incomprehensible and denied by many digital experts. However, there are a few brave souls who talk about phase problems causing this phenomenon.

Some digital to analogue converters (DACs) are much better than others but all depend on complex mathematical algorithms which are flawed in one respect or another. We highly respect and applaud those who manage to achieve acceptable results in this area as it’s incredibly challenging.

Compression Losses In Recording and Transmission

The results of recording a high-quality record player onto a digital recorder using a good digital convertor are surprising. The results can be very close to the original sound heard on the record player. The only standout area is the bass where digital never seems to quite get it (figures show 30% more distortion in the bass of CD players than turntables).

This seems contradictory at first so why is it an exception. Or to put it another way, why is the normal experience of digital not this good?

Firstly many CDs and digital sources are compressed to the extent that over 60% of the original information is lost. This enables faster production and download speeds but wrecks sound quality whatever the claims to the contrary. The compression process is inevitably flawed as is the decompression and conversion back to analogue.

Converting your Analogue to Digital

It’s possible to create genuinely high-quality digital recordings from Vinyl records that will far surpass the CD versions of the same records. Of course, it’s a complete disaster to expect a low-cost record player and phono stage to carry out this task as it’s simply “rubbish in, rubbish out”. This is where it’s essential to invest in a very high-grade turntable and phono stage plus a decent analogue to digital convertor.

The major advantage of doing this is that it will save your records from wearing when you only want to listen to your collection as background music. An added benefit is that you can listen to much higher quality music if you take it with you on the move.

What “high resolution & lossless” can really b

In an honest world, the words high resolution and lossless would be good news. The problem is that the whole truth is often not being told which is why these formats still sound terrible. You can take a low-resolution recording in a format such as MP3 and upsample it into a high-resolution format then call it high resolution. Problem solved? Far from it! This is like taking a blurred photograph and putting it through sharpening filters. The result will never come close to an authentic high-quality image taken in focus.

Why Analogue Recordings From Digital Sources Sound Better Than The Original Digital?

It’s a source of amazement to some, that many analogue vinyl records are made from digital recordings. How can they possibly sound better? The answer to this is almost certain that the process of converting digital onto a vinyl record is mechanical. This has the effect of “upsampling” the original digital signal from limited resolution into infinite resolution. The ear finds this more acceptable as it’s free of the digital artefacts which plague algorithm-driven conversion.

Michael Fremmer made an interesting remark that quite a number of turntable designers come from Silicon Valley and worked on designing chips for DACS (which convert digital to analogue). These individuals are fully aware of the flaws in chip designs and prefer turntables.

Published Magazine Article On Digital vs Analogue

Back in February 2004, Hi-Fi World asked me along with a number of others to contribute answers to a series of questions. I have republished my answers below as they have as much relevance now as they did then:

[1] THEORETICALLY, WHICH IS BETTER – DIGITAL OR ANALOGUE?

Theoretically, each format could claim superiority if the technology behaved perfectly. However, the discussion ultimately boils down to the fact that both mediums have technical issues to overcome. Which is better depends on the limitations of existing technology and knowledge. When CD was first launched, people sited the technical superiority of the medium over vinyl – better dynamic range, lower distortion etc. The same old rhetoric is being repeated for the new digital formats – In the effort to claim technical superiority and the advance of technology, the issue of subjective sound quality appears to have become merely incidental.

In spite of the claims for the new formats, it is plain that much is still not understood about the exact nature of digital. Things that look perfect on paper turn out to be far from perfect in practice. CD’s were eventually discovered to have up to 30% distortion in the bass which is nowhere near as good as vinyl. This is just one example but there is also a raft of other misconceptions – were the designers not aware of these problems?

The Unknown Difficulties

At face value it may seem straightforward to translate a digital code into analogue, so where does it go wrong? is it sampling rates? Even with the new high sampling rate formats, the translation from digital to analogue is bound to degrade the signal significantly. This is due to the limitations of the devices that read the information on the discs – not all the information is read perfectly and disc reading errors occur continuously. The electronics required to compensate for the ensuing mess has a host of side effects that are most unpleasant. Severe and complex problems lie in the multitude of activities that the electronics must perform. The outcome is that the new digital formats are severely flawed as far as the human ear is concerned.

Solutions?

According to a number of expert opinions outside the digital marketing departments, there are specific technical problems with the new formats which mean that they will never outclass vinyl in terms of sound quality. One easily understood issue is the “watermark” that is put on an increasing number of digital discs to prevent copying. This alone is known to cause significant sound degradation with no solution on the horizon. Yet another issue is the need to rectify disc reading errors – can a DTA converter really take an educated guess to fill in missing information with accuracy – it doesn’t appear so. A crude analogy of the problem is that of cutting up a prime fillet steak into tiny chunks – no matter how finely you cut it and try to put it back together, you still end up with a hamburger not fillet steak.

Vinyl analogue replay on the other hand has the following advantages

a) No sampling rate unless you call infinity a sampling rate.

b) The conversion of an analogue mechanical signal into the final analogue electrical signal is much simpler than a digital to analogue conversion.

c) The minimal errors of a cartridge do not need “correction”. Although distortion may be higher it does not have the “nasty” nature of digital distortion that is thoroughly offensive to the ear.

[2] WHICH SYSTEM DO YOU PERSONALLY PREFER – AND WHY?

Not surprisingly I prefer Analogue! It has a fluid sound quality as opposed to digital which can be distinctly edgy at times. There are numerous other subjective differences particularly in the bass region which is where analogue scores so heavily over digital. Analogue portrays an effortless and authoritative bass which forms the foundation of music. Digital sources seldom have this quality – partly because the digital recording itself has been rolled off early and no player can play the music that has simply been removed. However, in addition to this, the players seem unable to convey the warmth and subtleties present in the bass areas of the music. As for midrange, treble, and musicality, you only have to listen, and the superiority of vinyl is obvious to most people. There will be people who prefer digital but it may depend to some extent on the way they process music in their brain – some people prefer an electronic keyboard over a real piano.

WHAT ARE THE RELATIVE ADVANTAGES AND DISADVANTAGES OF ANALOGUE?

1) Analogue is now perceived as “the new high-end format” by those who have listened to modern turntables and phono stages. For out and out sound quality there is nothing to touch it and this state of affairs will continue due to the inherent problems of digital formats.

2) Many of the recordings on vinyl have not been wrecked by digital remastering and this alone is often highly significant. The phrase “digitally remastered” fills most analogue lovers with horror because they have heard the results – How some of the marketing men involved with the digital format get away with the total nonsense they deliver to an unsuspecting public is beyond me. It is also partly responsible in my view for the long term decline in cd sales. By this, I mean that although short term sales may seem to increase due to people believing false claims about superior sound quality, in the long run, many people wonder why they are finding their new “digitally remastered” recordings are not really touching them at an emotional level.

The disadvantages of analogue are the availability of records although this situation is steadily changing for the better as more and more recordings are repressed and made available through specialist internet mail order companies.

The cost of hardware for analogue is much less than digital (outside the budget end of the market) – in other words, a £1000 record deck will outperform a £12,000 CD player.

Turntables are wonderful looking pieces of kit – some of them resemble a work of art. This lends a certain romance to them that CD players don’t possess.

Turntables are upgradable with better tonearms, cartridges and power supplies. The upgrade path far surpasses digital as an investment because the performance ceiling is so much higher.

There are vast quantities of cheap 2nd hand vinyl around.

[b] DIGITAL?

ADVANTAGES

a) Digital is a very convenient medium and easy to record. It is a good successor to audio tape as it has better sound quality and does not suffer degradation with age unless badly treated.

b) CD’s can be played on portable ghetto blasters and car audio.

c) Convenience and flexibility – CD’s are small and portable, people can skip tracks using a remote control and the players are more fuss-free than record players.

DISADVANTAGES

Sound quality is hard, edgy, lacks timing, bass warmth and subtlety compared to analogue.

The lasers of CD players have a limited life. After 3 years your laser may easily breakdown and it is impossible to find a replacement due to the short lifespan of most players.

[4] WHY DO YOU THINK THE MUSIC AND AUDIO INDUSTRY MOVED TO DIGITAL IN THE

THE EIGHTIES?

The Industry moved to digital because of the following opportunities.

a) The incredibly poor quality of most record players of the day meant that CD would be perceived as a leap forward in sound quality. Hence there would be a big market for CD’s and the required hardware to play them. The claim of perfect sound quality on an indestructible disc would be highly attractive and perceived as true by the vast mass of people.

b) On a commercial basis, CD’s were cheaper to produce than vinyl records.

c) Digital had a wider market as CD’s were playable on portable ghetto blasters and car audio.

[5] WHY DO YOU THINK THERE WAS A VINYL REVIVAL IN THE NINETIES?

The revival was partly due to discerning listeners with decent record players – these individuals recognized that CD was actually a backward step in terms of a high-quality format The problem with vinyl had not really been a format issue but the low quality of most turntables. These individuals realized that pursuing better and better CD players was never going to make up for the fact that the medium itself was fatally flawed. By way of contrast, Vinyl players were making huge advances. We have now reached the current state of affairs in which the new Goldring turntable at £140 will outperform most CD players.

The DJ Influence On The Analogue vs Digital Debate

The other factor was that DJ’s still used vinyl. This partly explains why it is cool for youngsters to have a turntable in their room. DJ’s have an amazing following and are influential in their own right. The great bass quality of analogue is of course a key aspect for dance floors and apart from scratching this is another reason why it is the favoured medium of DJ’s. Night clubs are becoming more aware of the potential of analogue and have started fitting our arms to their technics decks with astounding results. Currently, one of the clubs in New York which use our arms has been shortlisted in the top 5 best sounding clubs in the world.

[6] DO THE NEW HIGH RES DIGITAL FORMATS (SACD, DVD-A) HAVE A FUTURE?